4 Guys History

4 Guys Fire Trucks, which marks its 50th anniversary in 2024, regards itself as a regional builder, consistently producing between 50 and 60 pieces of apparatus annually and boasting yearly sales in excess of $23 million.

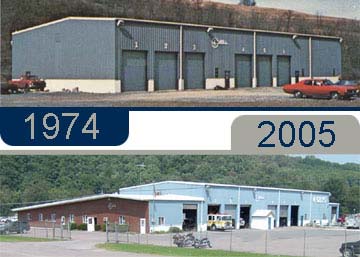

Steady Growth

In 1974 four local men with ties to the dairy industry started a business repairing stainless steel milk tankers. Shortly after 4 Guys was established, the company solicited new investors and shifted to building fire apparatus. In 1974 four local men with ties to the dairy industry started a business repairing stainless steel milk tankers. Shortly after 4 Guys was established, the company solicited new investors and shifted to building fire apparatus.

At first, the company built elliptical tankers based on their original milk tanker design. Soon, satisfied 4 Guys tanker owners started coming back, asking for pumpers and rescue trucks.

Today, 4 Guys produces nearly twice as many pumpers as tankers. The progression has been gradual, but as customer confidence has increased, 4 Guys has grown to meet the demand.

Production

"We're basically trying to put out one or two new units a week," says Mark Albright, 4 Guys President and CEO. About 60 percent of current production is pumpers, another 30 percent tankers and 10 percent rescues. "We've been growing every year, not by leaps and bounds, but it's been pretty steady," Albright adds.

The original building has been enlarged five times. Additions include a new paint booth, a truck finishing area, office areas and inspection bays. The plant now covers more than 30,000 square feet.

Albright, who has held the top position in the company since 1990, started at 4 Guys in 1982. The staff has more than doubled in the years he's worked for 4 Guys.

Albright, who has held the top position in the company since 1990, started at 4 Guys in 1982. The staff has more than doubled in the years he's worked for 4 Guys.

"Today, we have around 70 employees, which is a modest increase over 20 years ago," Albright says. "Our employee turnover is extremely low. That's one thing about this company - the owners treat the employees quite well and that means the people stay here." That leads to people who really know their jobs.

Albright says profit sharing and good benefits keep the workers happy and productive, which translates into a good product.

"Product quality is why we've lasted and grown over the years. The repeat business has been amazing. Fire companies keep coming back for new trucks," Albright says. "We've developed some great relationships with our customers over the years. Some of our customers have as many as five of our trucks."

Warranty and Customer Service

The company's philosophy is to keep the customers happy and "make it right" no matter what.

Nowhere is this more evident than in 4 Guys' 30-year warranty, which covers the body, subframe, pump house, compartment doors and all the stainless steel components the company constructs.

"I don't know of anybody else that offers such an extensive 30-year warranty," says Fred Meyers, the company's sales manager. "And there aren't many builders offering entirely welded stainless steel bodies. We believe that stainless is a superior product and that means we can stand behind a 30-year warranty."

The company's ability to customize each unit by working with the customer is an additional strength of 4 Guys.

Meyers, who has been with the company 29 years, explains: "We build one truck at a time. We're not a volume builder. Whatever a department wants, we try to provide. Each truck is engineered separately."

Engineering

It's the job of the engineering department to figure out the best way to do what the customer wants done. They also make sure that it's safe and NFPA compliant. The engineering department is headed by Bill Scherer, a mechanical engineer who has been with 4 Guys since 1993. Bill is assisted by 3 other engineers who use a computer drafting program called KeyCreator to produce wire-frame drawings of all units.

Typically, each drawing goes through several revisions before the truck is built.

Sales

4 Guys has about 20 salespeople in the field who work with customers, making suggestions and finding out exactly what the customer needs.

The sales force works mostly in the eastern United States, particularly in the Mid-Atlantic States, according to Meyers. "We're regarded as a regional body builder," he explains.

While 4 Guys has made deliveries as far away as California, the primary market is Pennsylvania, Ohio, New York, Virginia and surrounding states.

When the salespeople are out in the field, they are typically matched up against the sales staffs from the giants in the industry. With all this competition, what tips the balance in the favor of 4 Guys?

Quality

"For one thing, we're bidding stainless steel, which is a far superior product, but we're still very competitive on price," says Albright.

"For one thing, we're bidding stainless steel, which is a far superior product, but we're still very competitive on price," says Albright.

Having well-trained salespeople in the field promoting benefits and features of the products makes a big difference.

4 Guys warranty and customer service, attract customers, too. "When new customers check out our references," Meyers says, "they find that we back what we sell. Most often, people are going to buy trucks based on price and value."

Custom Designed - Custom Built

4 Guys is a custom shop. When customers come in for prepaint inspection, they spend their day on the shop floor, talking with the men who are building the truck.

Customers can ask questions, and the fabricators and finishers can ask questions of them. Through that exchange of ideas, the truck can be further customized to make a perfect fit for each customer.

Mike Lane, 4 Guys Production Manager, started as an electrician. He explains, "When a fire company leaves here, they feel really good because they know the guys who are building the truck know what they're doing. Often, when a customer calls with a question, one of the men on the floor will get right on the phone with them and help resolve it."

Mark Albright, who also works directly with customers after the sale, says he hears more positive comments about the shop workers than almost any other aspect of the truck-building process.

Future

"We're not as big as some of the other companies," Meyers says. "We pick up salesmen as we need to. We want to grow, no question, but we don't want to be big overnight."

Everything in the 4 Guys facility is company owned. "We have no debts, except our current accounts payable," says Meyers.

"A new fire truck is a big investment. Fire departments want to deal with a builder who will be there when they're needed. Not just next week, but next year and ten years from now. Because we have no heavy long-term financial burden, they know we'll be around," Meyers says. "4 Guys is dedicated keeping our workers employed. It benefits our small town to provide work. We've always worked hard for the business because it's vital to the economy of our region to keep this plant here. I believe that the strong independent companies will survive. I think there's still a market for the custom builder; and that's what we are."

|