THE "NEW TRUCK PROCESS"

Let's start with an invitation to visit our manufacturing plant. Once you see the quality

of our materials and workmanship, we're confident you'll take as much pride in owning a 4 Guys truck

as we do in building them.

In order to get the new truck process rolling, you'll need to contact

us. Then our sales manager or the sales representative for your area will get some basic information about your

department and the type of truck you're looking for. We'll also set up an initial meeting as soon as

it's convenient for your department.

At that meeting our representative will present a preliminary specification based on your information and will review it

with your truck committee. This gives your committee the opportunity to ask questions and get directly involved in the process of streamlining

your specs.

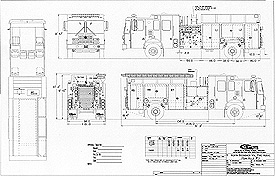

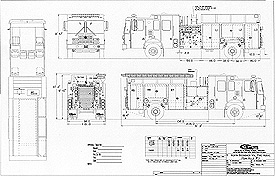

After the initial meeting, the specs are turned over to

4 Guys engineering department, where your detailed CAD

blueprints will be produced. We'll send them out so you can see what you've specified,

instead of just reading about it. When you review the drawings, you're

sure to think of something else. Discuss any changes with your sales

representative and note them on the drawing. Then we'll adjust the drawing

to your notes.

Once you're satisfied with what you've chosen, we'll sign a

contract with your fire company. Among other things we'll guarantee that

your new unit comply with all current NFPA regulations.

Then it's time to order the chassis. We can order your HME or Spartan

custom cab & chassis, or a wide variety of commercial chassis. If you

prefer, you can even order your own chassis through your local dealer, as

long as its specs are approved by 4 Guys engineering

department.

The first thing that happens when your chassis arrives at

4 Guys is the pump installation. We can use, at your option, Hale,

Waterous

or Darley fire pumps.

While the pump is

being installed, the body fabricators at the other end of the shop will

be building the body according to your blueprints. Whenever possible,

compartments are made from a single sheet of material. This, along with

continuous welding of all compartment seams, eliminates the possibility

of leaks. 4 Guys bodies are made entirely from Everlasting 304

grade stainless steel. This even includes the parts you can't see, such as the body

frame crossmembers. We do use some aluminum, but never as a part of

the body fabrication process. Because its strength and durability

are considerably less than stainless, aluminum parts are added only at

the finish stage to dress up the truck's appearance. While the pump is

being installed, the body fabricators at the other end of the shop will

be building the body according to your blueprints. Whenever possible,

compartments are made from a single sheet of material. This, along with

continuous welding of all compartment seams, eliminates the possibility

of leaks. 4 Guys bodies are made entirely from Everlasting 304

grade stainless steel. This even includes the parts you can't see, such as the body

frame crossmembers. We do use some aluminum, but never as a part of

the body fabrication process. Because its strength and durability

are considerably less than stainless, aluminum parts are added only at

the finish stage to dress up the truck's appearance.

Our hinged doors are another feature that sets

4 Guys apart from most other manufacturers. Our doors are fully

reinforced. They're perfectly fitted to close tightly every time.

They're mounted with full length stainless steel hinges. And they're

less than an inch thick, allowing for maximum useable compartment depth!

Once

the pump installation is complete, the body, which has been fabricated

separately, is lifted with a crane and installed on the chassis. By

building the body this way, we can easily remove the entire body should

any future repairs be necessary. Using "U" bolts allows us to fasten the

body to the chassis without welding or drilling the truck frame. A strip

of 1" rubber is used to insulate the body against shock. Once

the pump installation is complete, the body, which has been fabricated

separately, is lifted with a crane and installed on the chassis. By

building the body this way, we can easily remove the entire body should

any future repairs be necessary. Using "U" bolts allows us to fasten the

body to the chassis without welding or drilling the truck frame. A strip

of 1" rubber is used to insulate the body against shock.

After the body is placed the tank is set into

place, (except in the case of elliptical tankers, that have the tank

integral to the body) and the plumbing is run.

Four Guys features UPF Poly tanks, allowing us

the versatility to offer nearly unlimited options, including suction

hose compartments under the "T" of the tank, ladder compartments through

the tank, and integral foam cells for Class "A," Class "B,"

and AFFF foam systems.

At this point in the construction process, you and

your fire department's representatives are encouraged to inspect the

truck and indicate any last-minute changes. You'll be free to take

pictures and ask as many questions as you want. This is your "pre-paint

inspection."

At this point in the construction process, you and

your fire department's representatives are encouraged to inspect the

truck and indicate any last-minute changes. You'll be free to take

pictures and ask as many questions as you want. This is your "pre-paint

inspection."

With the booster tank and the plumbing in place, the

truck moves to our in-house paint shop. Here, any low spots left by the

fabrication process will be filled and sanded. The entire truck is

cleaned and appropriate areas are masked. The truck is then moved into

the spray booth and painted according to the instructions we received

from your department at pre-paint.

The pump panel, electrical, and finish departments

take over when your truck comes out of the paint shop. The panel men are

charged with laying out your top, side, rear or compartment mounted pump

operator's panel in a manner that's easy to understand, even to the

first-time operator. While we're flexible on panel layout, we don't

think you'll find one that's easier to use than our standard layout.

The pump panel, electrical, and finish departments

take over when your truck comes out of the paint shop. The panel men are

charged with laying out your top, side, rear or compartment mounted pump

operator's panel in a manner that's easy to understand, even to the

first-time operator. While we're flexible on panel layout, we don't

think you'll find one that's easier to use than our standard layout.

The electrical department is responsible for

mounting and wiring all the lights in the body, including DOT & NFPA

lights, as well as compartment and scene lights. 4 Guys

electricians also wire the radios, sirens, shore-line receptacles and

all other electrical equipment. All wiring is COLOR coded and labeled to

eliminate confusion. Wiring originates at a concealed breaker panel

that's small enough to fit in a compartment door jamb. Protective loom

shields all wiring from dampness and corrosion.

The finish men, as the name implies, add all the

accessories that make the truck look "finished." The tops of the

compartments, running boards, and the step areas are covered with

aluminum diamond plate. Folding steps are added according to your fire

department's instructions and NFPA regulations. Grab handles are

installed, along with brackets to mount ladders, Fol-Da-Tanks and other

accessories. At this stage, the body doors are installed and the paint

is buffed to bring out the shine. When all this is done, the truck is

lettered. This, too, is done to the fire department's specs, and in most

cases, it is even possible to closely match existing trucks.

The finish men, as the name implies, add all the

accessories that make the truck look "finished." The tops of the

compartments, running boards, and the step areas are covered with

aluminum diamond plate. Folding steps are added according to your fire

department's instructions and NFPA regulations. Grab handles are

installed, along with brackets to mount ladders, Fol-Da-Tanks and other

accessories. At this stage, the body doors are installed and the paint

is buffed to bring out the shine. When all this is done, the truck is

lettered. This, too, is done to the fire department's specs, and in most

cases, it is even possible to closely match existing trucks.

Once this stage is reached, the truck is ready for

its NFPA and UL tests and certifications, after which it can be picked

up and placed in service by your department.

Return to Top

|

While the pump is

being installed, the body fabricators at the other end of the shop will

be building the body according to your blueprints. Whenever possible,

compartments are made from a single sheet of material. This, along with

continuous welding of all compartment seams, eliminates the possibility

of leaks.

While the pump is

being installed, the body fabricators at the other end of the shop will

be building the body according to your blueprints. Whenever possible,

compartments are made from a single sheet of material. This, along with

continuous welding of all compartment seams, eliminates the possibility

of leaks.  Once

the pump installation is complete, the body, which has been fabricated

separately, is lifted with a crane and installed on the chassis. By

building the body this way, we can easily remove the entire body should

any future repairs be necessary. Using "U" bolts allows us to fasten the

body to the chassis without welding or drilling the truck frame. A strip

of 1" rubber is used to insulate the body against shock.

Once

the pump installation is complete, the body, which has been fabricated

separately, is lifted with a crane and installed on the chassis. By

building the body this way, we can easily remove the entire body should

any future repairs be necessary. Using "U" bolts allows us to fasten the

body to the chassis without welding or drilling the truck frame. A strip

of 1" rubber is used to insulate the body against shock.

At this point in the construction process, you and

your fire department's representatives are encouraged to inspect the

truck and indicate any last-minute changes. You'll be free to take

pictures and ask as many questions as you want. This is your "pre-paint

inspection."

At this point in the construction process, you and

your fire department's representatives are encouraged to inspect the

truck and indicate any last-minute changes. You'll be free to take

pictures and ask as many questions as you want. This is your "pre-paint

inspection."

The pump panel, electrical, and finish departments

take over when your truck comes out of the paint shop. The panel men are

charged with laying out your top, side, rear or compartment mounted pump

operator's panel in a manner that's easy to understand, even to the

first-time operator. While we're flexible on panel layout, we don't

think you'll find one that's easier to use than our standard layout.

The pump panel, electrical, and finish departments

take over when your truck comes out of the paint shop. The panel men are

charged with laying out your top, side, rear or compartment mounted pump

operator's panel in a manner that's easy to understand, even to the

first-time operator. While we're flexible on panel layout, we don't

think you'll find one that's easier to use than our standard layout.

The finish men, as the name implies, add all the

accessories that make the truck look "finished." The tops of the

compartments, running boards, and the step areas are covered with

aluminum diamond plate. Folding steps are added according to your fire

department's instructions and NFPA regulations. Grab handles are

installed, along with brackets to mount ladders, Fol-Da-Tanks and other

accessories. At this stage, the body doors are installed and the paint

is buffed to bring out the shine. When all this is done, the truck is

lettered. This, too, is done to the fire department's specs, and in most

cases, it is even possible to closely match existing trucks.

The finish men, as the name implies, add all the

accessories that make the truck look "finished." The tops of the

compartments, running boards, and the step areas are covered with

aluminum diamond plate. Folding steps are added according to your fire

department's instructions and NFPA regulations. Grab handles are

installed, along with brackets to mount ladders, Fol-Da-Tanks and other

accessories. At this stage, the body doors are installed and the paint

is buffed to bring out the shine. When all this is done, the truck is

lettered. This, too, is done to the fire department's specs, and in most

cases, it is even possible to closely match existing trucks.